The brinell hardness test ing uses indenters made of st eel to test materials with hardness values of up to 350 hb or of hard metal tungsten to test materials with har dness values from 350 to.

Brinell hardness testing machine pdf.

Practical hardness testing made simple 9 3.

Indentec hardness testing machines limited is a manufacturer and supplier of hardness testing machines accessories test blocks and indenters we have a service department for after sales support offering regular ukas accredited recalibration visits and repairs.

Usb camera with front touchscreen hmi.

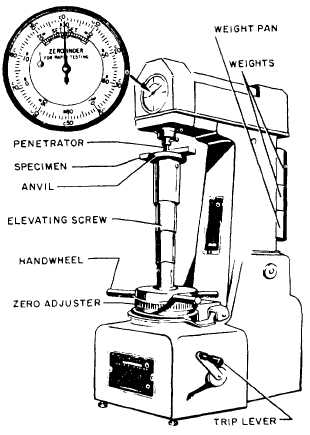

Rockwell hardness test with diamond cone indenter rockwell c.

As specialists we can also offer bespoke fixtures and automatic systems to ensure your specific needs are met.

3 1 3 standardization to bring in conformance with a known standard through verification or calibration.

Fully computerized touchscreen brinell hardness testing machine.

Simple accurate measurement technique.

An initial force called pre load of 98 1 n fo is applied.

Wilson hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable blocks available.

The full load is.

Diamond cone with an angle of 120 at the summit and ending with a radius of 0 2 mm.

Automatic measurement of the indentation to give brinell hardness tester.

Front panel touchscreen display.

3 1 2 the brinell hardness test the brinell hardness test method consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball subjected to a load of 3000 kg.

The brinell hardness test is used to determine the hardness number of hard moderately hard and soft material e g.

One of the most popular hardness testing methods brinell hardness number is obtained using a perfectly spherical hardened steel ball of 10 mm pressed against the test surface using a static force of 3000 kg 29 42 kilonewton for at least 10 seconds for steel and measuring.

3 1 4 brinell hardness test an indentation hardness test using a verified machine to force an indenter tungsten carbide ball with diameter d under specified conditions into the surface of the material under test.

Brass br onze aluminum gold and copper.

Suitable for measuring the hardness of precision metallic parts.

In this phase the indent depth reader must be zeroed.